Nissan To Expand The Usage Of High-Tech Steel To Reduce Emissions

所有资讯Nissan launched a sustainability plan earlier this month that demands for lowering CO2 emissions from its new vehicles by 40% by fiscal year 2022, compared with fiscal year 2000.

As such, the company is planning to expand the use of ultra-high tensile strength steel, aiming for it to make up 25% of the company’s vehicle parts by weight.

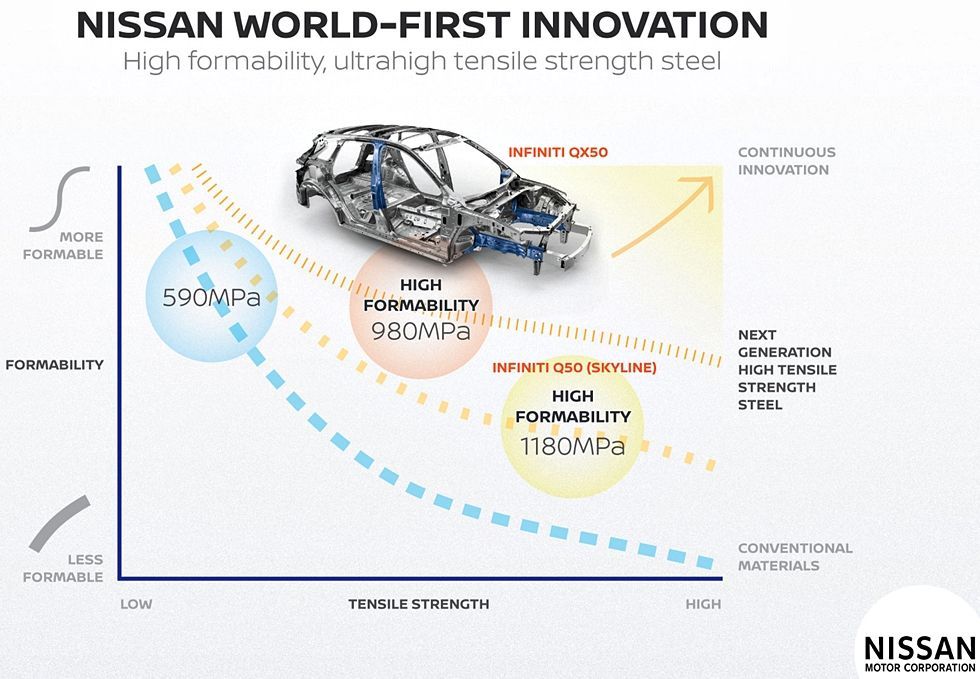

The all-new Infiniti QX50, which went on sale in the USA in March, represents the first automotive use of SHF (Super High Formability) 980 MPa high-tensile steel, further strengthening the all-new platform.

The high-tensile material, jointly developed by Nissan and Nippon Steel & Sumitomo Metal Corp., can be moulded into unprecedented shapes, saving weight and representing a torsional rigidity improvement of 23 percent over the outgoing model. This rigidity allows the car to resist flex and vibrations while reducing the noise transmitted to the cabin. This material makes up 27% of the new QX50.

In terms of manufacturing process, the new SHF high-tensile steel can also be cold-pressed, thus help contain increases in vehicle cost.