Mercedes-AMG's Turbo 2.0-litre Is The Most Powerful 4 Cylinder In Series Production

所有资讯Just when you thought Mercedes-AMG couldn't put any more performance in their smallest model, they've gone and done it again. The old Mercedes-AMG A45 was already a stunner with 381 PS and 475 Nm of torque in its final iteration, but the up and coming model will see that number rise to 421 PS and 500 Nm of torque courtesy of the all-new M139 turbocharged 2.0-litre 4-cylinder engine. The changes are numerous - far more than just upping the size of the turbocharger or boost levels.

For one, placement of this engine is now completely reversed, with the exhaust side facing the firewall and intake side facing the front. This in turn gives the engine better routing for piping and better response as a result of shorter lengths and improved component placement, as well as improved aerodynamics. It may make the turbocharger a little more difficult to access, but it definitely helps from a performance and balance standpoint.

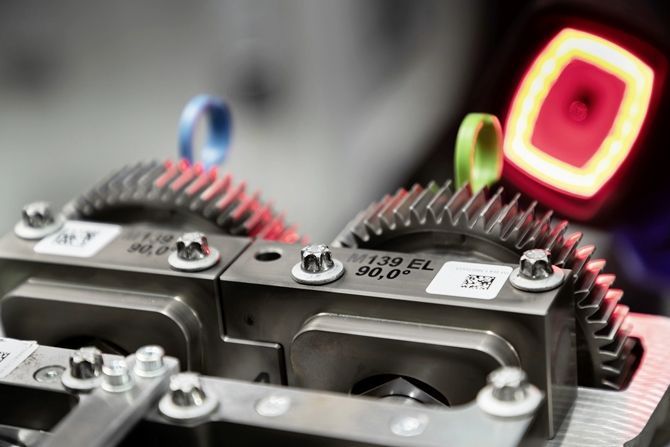

In comparison to the old engine, this M139 gets larger exhaust valves as well for better flow. More important than that is Mercedes-AMG has included the CAMTRONIC system, which was surprisingly not present in the older M133. The system offers both variable cam timing and variable lift, and it does so in a manner not unlike traditional dual-profile VTEC systems in Honda's highest performance naturally aspirated engines.

The only difference is that instead of locking the camshaft rockers to the higher cam profile, the system slides the cams forwards and backwards to nudge the rockers into either high or low lift and duration positions. In simple terms, it provides more flexibility for the power band and better low and high end performance. It only features on the exhaust cam, while the intake cam makes do with simple variable timing to speed up spool times by reducing valve overlap.

New turbochargers are expected, and roller bearings are a new addition to the hardware of the rotating assembly. This in turn improves response by lowering friction between the turbine and the housing, while a twin scroll setup divides exhaust pulses from consecutively firing cylinders in order to reduce turbocharger lag and interference between cylinders. When chasing big power, larger turbochargers are always necessary and engineers have to pull out all kinds of tricks to cut the resultant turbo lag down.

The fuel injection system has been updated to fire in multiple phases: the direct injection half of the equation is maintained at 200 bar fuel pressure, but a 6.7 bar port injection system has been added because as we've discovered in recent years, direct injection systems are still inferior to port injection when it comes to outright power. We don't yet have systems sophisticated enough or components strong enough to accurately supply fuel at higher rpms, so port injection provides enough additional fuel to keep the engine happy.

Even the ancillaries have been revised. The tech savvy among you may know of electric water pumps being used in motorsport applications, and they are fast becoming common in road cars. We're not referring to auxiliary electric water pumps, but rather the entire system. From an engineering standpoint, a traditional engine driven water pump works entirely opposite to what's needed: at low speeds such as stop-start traffic, the water pump should be pumping quicker as there isn't enough air flowing through the radiator, while at higher speeds a water pump should be operating slower to reduce losses. An electric water pump allows for precise control over pressure and pumping as and when it's needed.

And therein lies the beauty of this all-new engine. It's easy to say that there have been a number of high performance turbocharged 2.0-litres over the years that either match or eclipse these figures, but the reality is that none of these engines have ever been as technologically advanced or as responsive, or likely as reliable. The Mitsubishi Lancer Evolution FQ models come to mind as being the closest, but they were notoriously laggy in power delivery and were developed by Ralliart - not quite off the production line.

What most people forget is that as close as Mitsubishi came with the Evolution models, the powertrains were at the end of their lifespans. In the case of the infamous 4G63T that powered every Evo model up to the 9, it simply wasn't going to be able to develop the requisite power after tuning it to meet tightening emissions. Despite Mitsubishi's best efforts, the 4B11T in the final iteration of the Evo is frowned upon as being inferior in a variety of ways to its predecessor - although these were necessary moves to get the car into production.

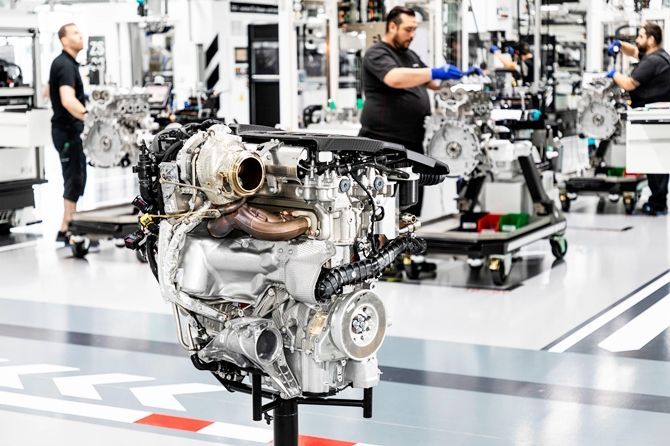

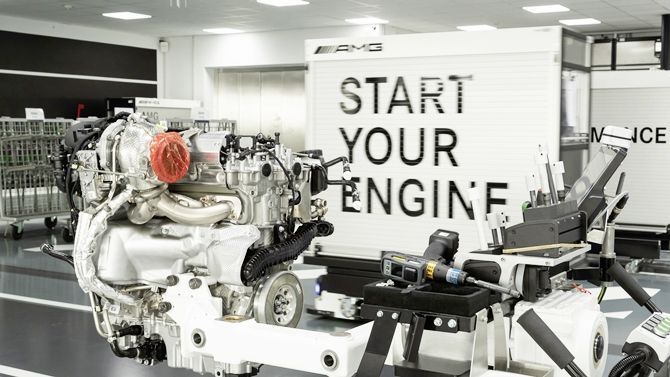

It's an impressive effort on the part of Mercedes-AMG, and the M139 will be hand-built as top-tier AMG engines are, although the processes are now far more streamlined to ensure that production can keep up with demand. The engine will feature in a few different models, with these performance figures being the very top-specification variant operating at 2.1 bar of boost, and a tamer 387 PS variant that runs at 1.9 bar of boost.