A Detailed Look Under The Audi E-Tron EV

InsightsAudi recently launched their first-fully electric vehicle, the Audi e-tron. Unlike other car manufacturers who debut their electric vehicle (EV) in a form of an oddly-shaped compact hatchback, Audi has decided to begin their no-emission product line-up with an SUV.

We followed Audi to their Audi Charge Tech Park to learn more about the inner workings of the new EV.

Styling

While the exterior styling of the Audi e-tron is basically a sporty-looking SUV, the final design was actually selected based on the best aerodynamic performance in the wind tunnel.

The sloping roof is both form and function, giving the e-tron a sporty silhouette from the side, and yet returning lower aerodynamic drag. The roof tapers smoothly to the angular D-pillars which meet the muscular ‘Quattro’ flared fenders where the set of wraparound tail lamps designate the next-third of the design approach.

The designers also added some clever design elements to highlight ‘electrified vehicle’, where the lamps have the graphic of horizontal bars that represent the charge level of batteries.

The lower portion of the doors and rear bumper have a strong pattern in contrasting colour to communicate the placement of the battery, the source of energy for the e-tron. The usual placement of the exhaust outlets is simple stylized elements now.

The brake calipers are also painted orange, the colour used for high-voltage cables.

Virtual Side Mirrors

This feature is by far the most impressive piece of technology on the Audi e-tron. The entire system is fully integrated into the vehicle design and architecture from the very beginning of the project.

Audi wanted to remove as much aerodynamic drag (plus wind noise) as possible and it was only through the fitment of the virtual side mirrors (VSM) that they managed to reach their target values.

Fitting the VSM lowered the Coefficient of drag (Cd) value from 0.28 to 0.27, the best in its segment.

Mounted on a slim stem painted in gloss black on both doors is a small camera with a resolution of 1,280 x 1,080 pixels. The captured images appear on 7-inch, high-contrast OLED displays positioned just below the top edge of the doors.

Thanks to sophisticated image processing, the displays adapt to the driving speeds as well as environment. At highway speeds, the image is reduced in scale so that the driver can better estimate speeds.

When the indicators are turned on, additional coverage to the side is displayed to reduce the blind spot.

Audi engineers say it only takes around 20 minutes for the drivers to familiarize themselves to the placement of the OLED displays and the absence of the physical side mirrors.

Electric Motors

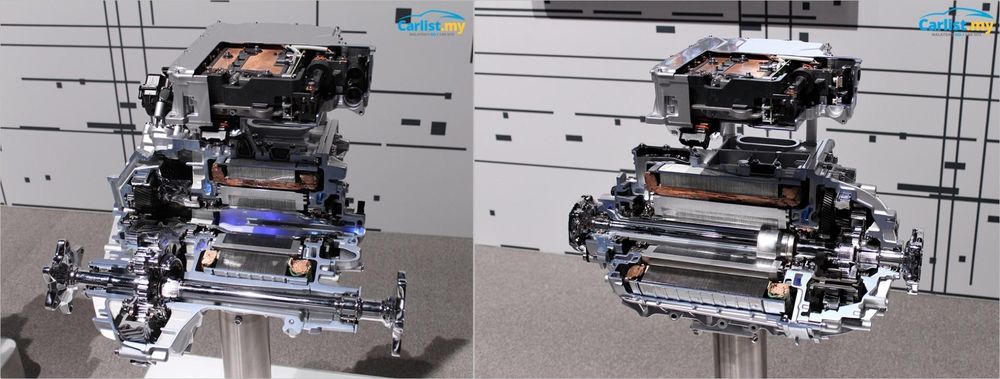

Two electric powers will provide traction for the Audi e-tron. The front motor can deliver 125 kW (170 hp) with 247 Nm of torque, while the larger rear motor, delivers 140 kW (190 hp) with 314 Nm of torque. The combined system output of 265 kW (360 hp) and 561 Nm propels the circa 2,500 kg electric SUV from standstill to 100 km/h in 6.6 seconds.

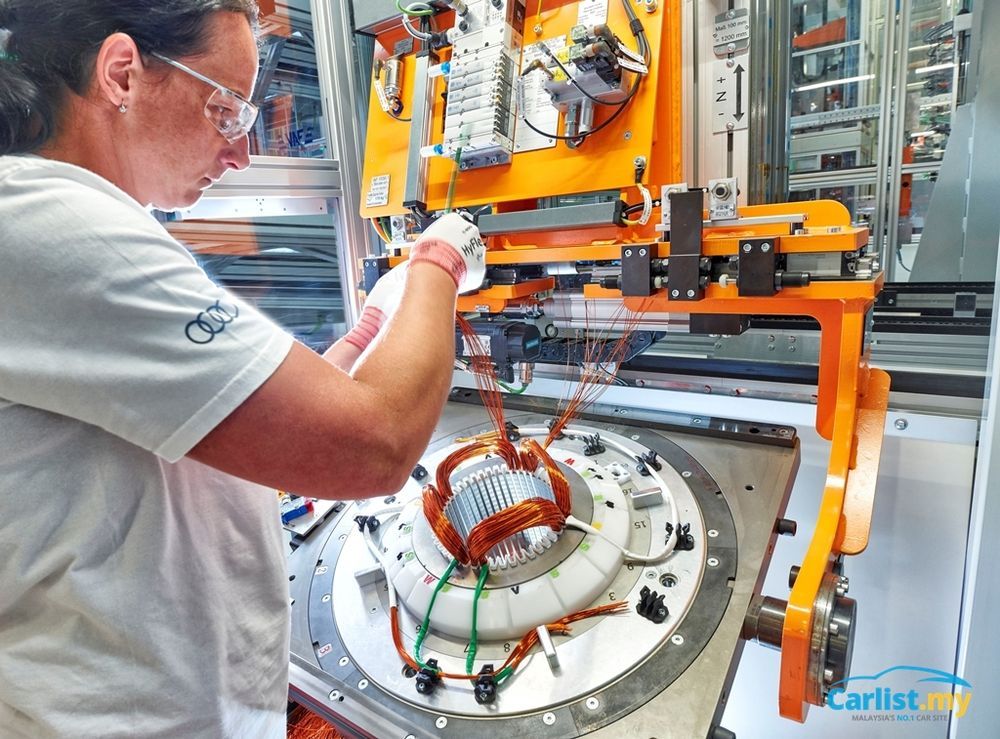

Each motor has its own power electronics and planetary gearbox, with a dedicated cooling system going into the core of each motor (rotor).

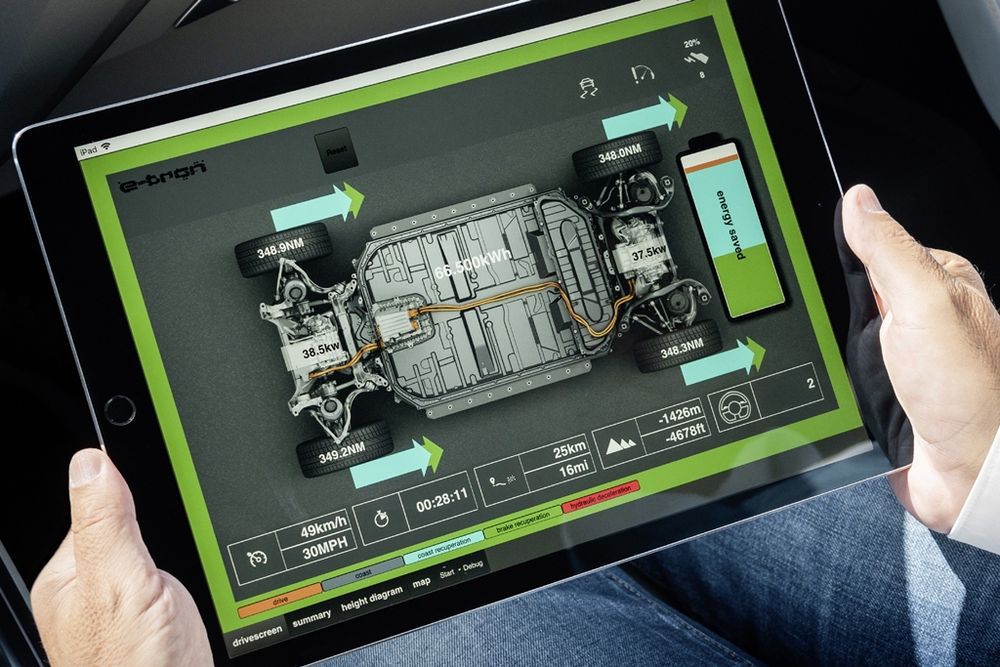

During normal driving conditions, drive is provided by the rear electric motor. If the driver demands more power, the front motor distributes additional torque. With traction available on all four corners, the e-tron also debuts a new generation of Quattro.

Audi says with the ultra-quick response of electric motors, the e-tron Quattro system is much better than the conventional system, and as such, providing even better agility and stability.

With the accelerator pedal fully depressed, the dual electric motors enter into Boost mode. The front and rear motor outputs now peak to 135 kW (184 hp) / 309 Nm and 165 kW (224 hp) / 355 Nm respectively.

The total system output of 300 kW (408 hp) and 664 Nm of torque dramatically improves the benchmark acceleration, slashing nearly a second to 5.7 seconds. For comparison, that is quicker than a Porsche Cayenne V6.

The fitment of the two large capacity motor-generator units also allows for more energy recuperation, or commonly known as regenerative braking. Audi allows the driver to select the “strength” of the regenerative braking, with the highest setting providing up to 0.3 G of deceleration force.

An interesting fact, the motors are made by Audi themselves their biggest engine plant, Audi Hungary.

Battery

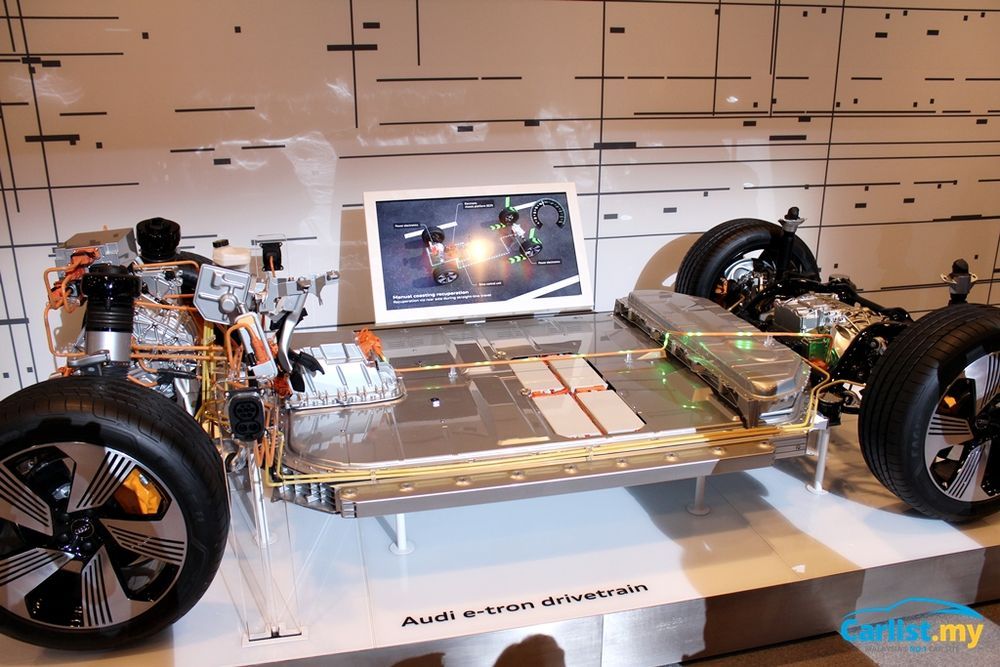

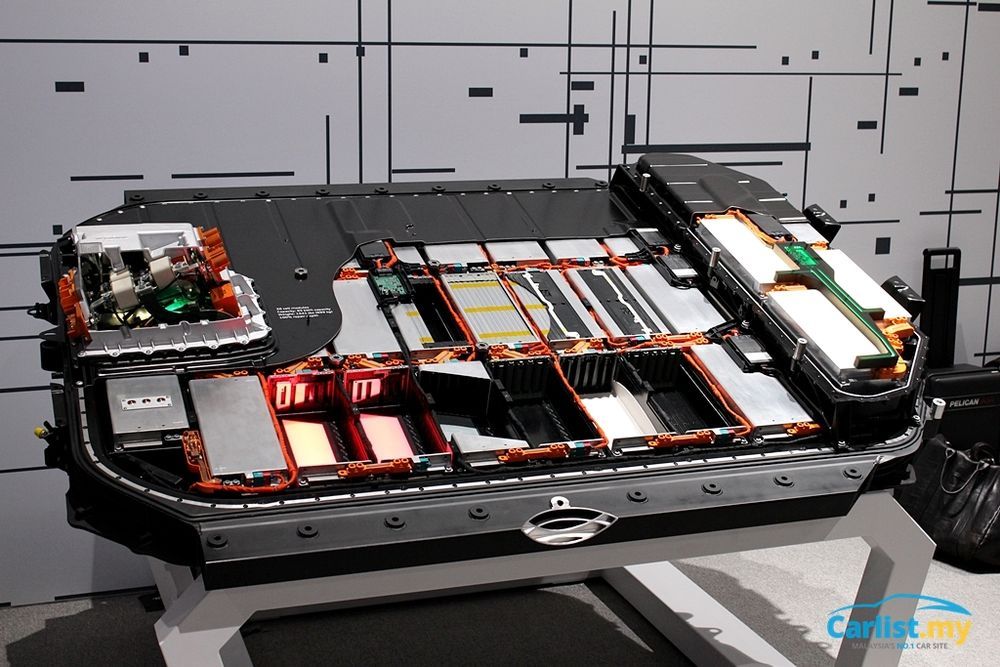

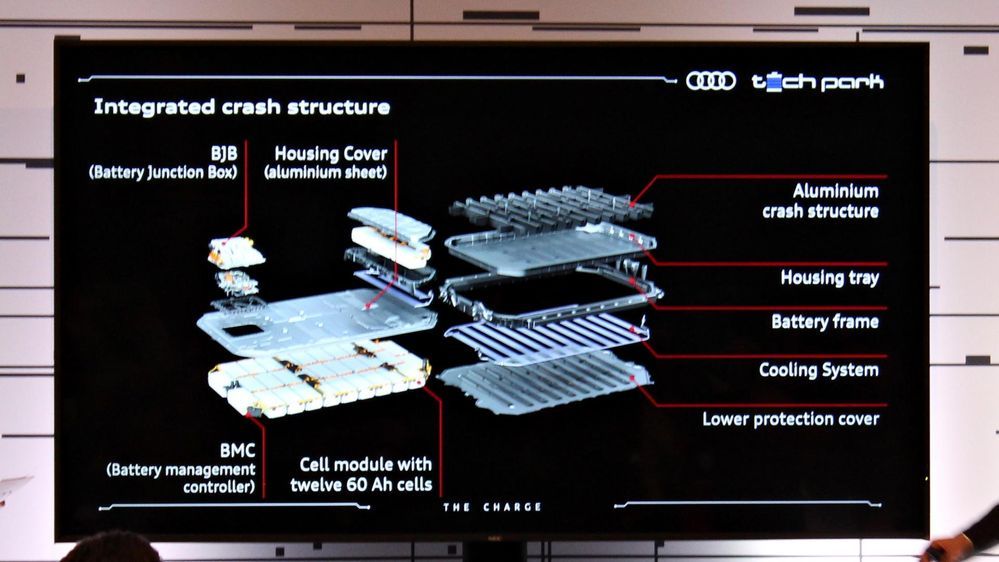

The massive 95 kWh battery pack is neatly placed below the floor of the Audi e-tron and does not protrude into the luggage area or passenger's foot well. Measuring close to 2.3 meters long and 1.63 meters wide, the battery pack is actually even larger than a king-sized mattress!

With current lithium-ion battery technology, the size needed to be as such to deliver customer-expected long driving range, which is claimed to be over 400 kilometres under the WLTP-test cycle.

Even with extensive use of cast and extruded aluminium pieces that form the protective shell, the battery pack weighs around 700 kilograms. Just for comparison, a 2018 Formula 1 racer weights just 733 kilograms inclusive of driver, a Formula E Gen-2 tips the scales at 900 kilograms, and the lightest Perodua Axia weighs just 820 kilograms.

The final assembly of the battery pack (12 cells packed into 36 modules) is again done in-house, at the Brussels plant.

High Capacity Cooling System

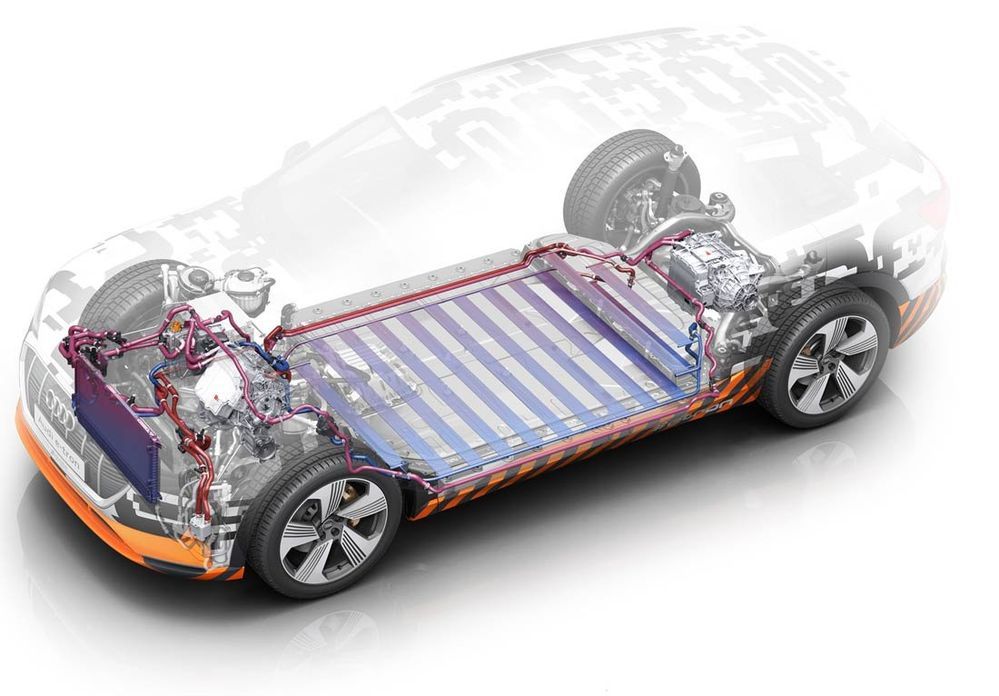

Both motors and the battery packs all have independent cooling systems. Coolant is pumped into the power electronics and then into the motor core before being returned to the radiator.

The battery pack, with houses many individual modules, use a more concentrated heat transfer technology. A thermally conductive gel is placed between the battery modules and cooling sheet beneath, to ensure the battery pack is kept in its optimal operating temperature range of 25 degrees to 35 degrees Celsius.

The battery cooling system also has its own refrigerant, as this is necessary to keep the temperature of the battery pack as well as other electronics under control during 150 kW DC charging.

As mentioned earlier, the front and rear motors each have their own cooling system, that proving cooling the power electronics as well as the surrounding (stator) and core of the motors (rotor). Heat from the planetary gearbox is also transferred away through clever design of the coolant path.

A total of 22 litres of coolant flow through close to 40 metres of plumbing in the Audi e-tron.

The Future

The Audi e-tron is the first of a few EV models that Audi has planned. After the launch of e-tron SUV, Audi plans to introduce the e-tron Sportback in 2019, and is followed by a compact model and a large-GT model in 2020, which executives say it is Audi’s version of the Porsche Taycan.

The company targets to have sales of 800,000 electrified vehicles by 2025, which represents a third of their total sales. Audi and Porsche are also developing ‘Premium Platform Electric’ (PPE) which will be the basis of the groups EV models from the year 2021.