Understanding Turbochargers

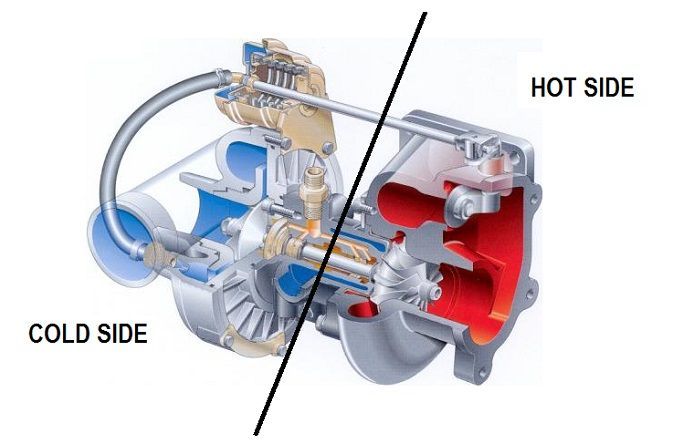

Live Life DriveA turbocharger is something you hook up to the engine to compress and feed air into the intake for more power. Breaking it down further, a turbocharger has a hot side and a cold side. The hot side is where exhaust gas from the engine goes into the hot side housing, and this fast moving gas spins a turbine. The turbine is connected by a shaft to the other half of the turbo, known as the cold side. On this side, a compressor wheel spins as it is driven by the hot side turbine, and it draws in air from outside and compresses it to higher pressure within the cold side housing.

But not all turbochargers are made equal. We’re not referring to the unique characteristics of turbochargers from different manufacturers, but rather the sizing itself. Using the term “big turbo” or “small turbo” can be misleading and requires a point of reference. Let’s instead look at it in terms of hot side and cold side housing sizes, and let’s look at engines in terms of how much exhaust gas flow they produce.

As a very rough example, a 1.5-litre engine may produce the same exhaust gas flow at 3,000 rpm that a 3.0-litre engine will produce at 1,500 rpm. This means that if a particular turbo were to only produce peak boost at 3,000 rpm on the 1.5-litre engine, it may be able to produce the same peak boost at 1,500 rpm on the 3.0-litre engine.

Exhaust gas flow increases with rpm, which is why a turbo spins more quickly as your rpm goes up. There is a physical limit to how fast the turbocharger can spin, which is why a waste gate is used to bleed off excessive exhaust gas flow to prevent over-speeding the turbo.

How quickly a turbo reaches operating speed (peak boost) comes as a result of the hot side sizing. A small hot side takes less exhaust gas for it to reach operating speed, but it can only take a certain amount of gas before it chokes (read: cannot spin any faster). A larger hot side may take more exhaust gas flow to get the turbo up to speed, but it will also be able to take more exhaust flow before it reaches a choke point.

The cold side sizing determines how much air the turbocharger can actually compress, but this end is restricted by the size of the hot side. In general you cannot slap on a massive cold side onto a small hot side for a quick-spooling turbocharger that produces massive amounts of boost. This will result in surging that will break a good many things in your engine.

The other thing to take into consideration is a simple fact: it doesn’t really matter how big your engine is. At the end of the day, the power output of your engine is governed by the amount of air you can force into your engine, because that in turn determines how much fuel you can put in. The only benefit of larger displacement is having more exhaust gas flow to spool the turbo up earlier in the rev range.

When you run a turbocharger at its maximum speed, the amount of boost pressure produced is as much as you will get, whether you’re running a 1.0-litre engine at some crazy rpm, or a 5.0-litre V8 with low end torque. The only way to produce more power is to use a turbo with a larger cold side, and in turn a larger hot side- which in turn also means you get a little more lag.

What this means is that for your “optimal” amount of power with the least amount of lag, you should be picking a turbocharger that is designed to flow just enough (or a little more than enough) air to produce the power you want. Anything larger introduces more lag for power you aren’t using, and anything smaller is likely to choke unless you run a more effective intercooler, or do some extensive head work, or run a watermeth/nitrous setup- but the fact remains that turbo sizing is the most important part of a forced induction build, and everything else you do is simply to support the kind of power you produce.